DarkWave Thermo relies on FLIR cameras for building diagnostics in the city of Mila

DarkWave Thermo’s certified facade analysis specialists use FLIR thermal imaging cameras to investigate detachment of tiles and wall cladding.

Maintenance work related to coated building facades has always required a lot of manual labor, including manual investigation as well as the installation of lift systems and safety scaffolds. Fortunately, FLIR’s thermal imaging cameras have proven to be an ideal tool to reduce labor costs and increase the effectiveness of building façade inspections.

Building facades come in many flavors. For a variety of reasons, including aesthetics and enhanced durability, building owners sometimes choose for more expensive coating materials than normal plaster, such as stone, marble, tile, and even other technological materials in order to give the building a more modern outlook.

However, these coatings can become detached from the wall façade, due to weather conditions, ageing materials or even faulty installation. Needless to say that these detached materials present a serious danger, not only for the integrity of the facades, but more importantly for the safety of people near the building.

Building façade quality inspections

Luca Del Nero, the founder of DarkWave Thermo, a thermal building inspection company, located in the North Italian city of Brescia, has many years of experience with this type of building inspections. The company has been doing a lot of inspections jobs in Milan, a city where historical buildings and beautiful architecture are abundantly present.

“Inspection jobs like those in Milan require first and foremost setting up a safety zone around the building,” he says. “Then, affected areas with detached materials need to be determined and quantified. In the case of small buildings, the general condition of the coating layer can be determined with manual inspections and detachment tests, in a relatively fast way and with limited expense.”

Large or complex buildings however are a totally different story. In these situations, when the location and size do not allow the use of lifting equipment or when manual inspection would be a long and costly process, infrared thermography is the technology of choice.

Thermography for building inspections

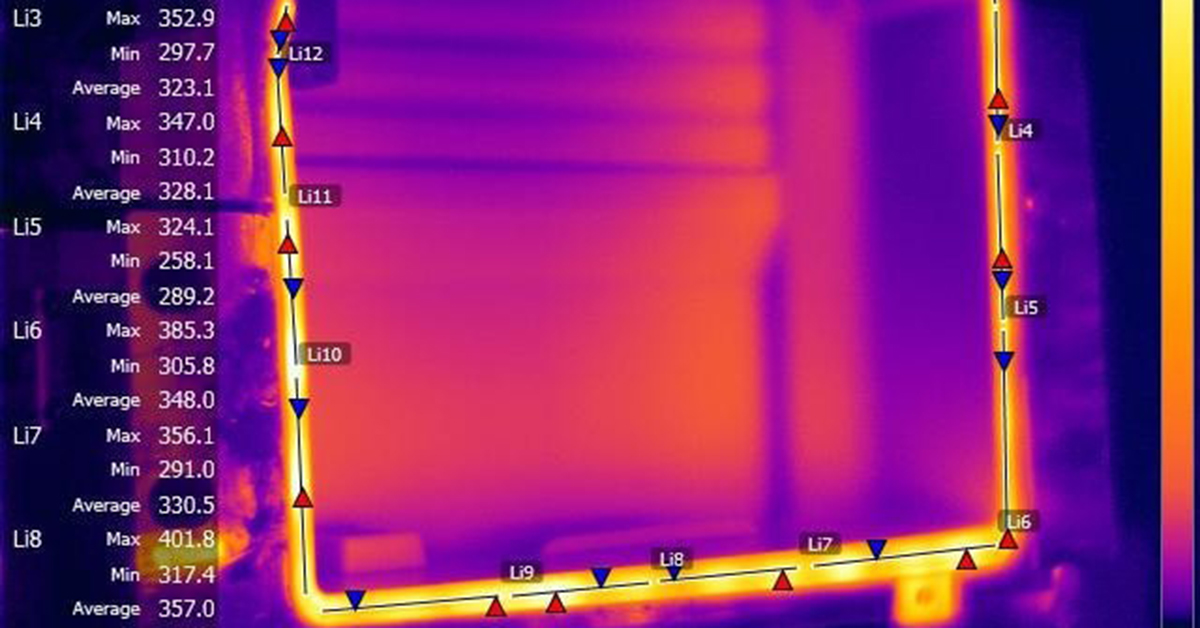

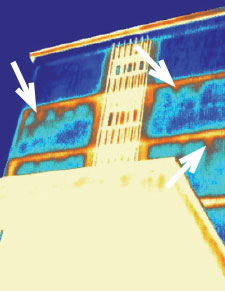

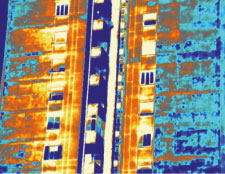

Under the right conditions thermal imaging can easily and clearly highlight the surfaces subject to detachment. In figures 1 – 3, the irregularly shaped orange areas clearly indicate the presence of detached coatings (highlighted by the arrows). To check the detachment of plaster or tiles, it is critical to make use of the right lens and to plan the inspection job in a time slot with the perfect sunlight conditions. In fact, well-bonded tiles or plaster behave very differently from material that is not firmly attached. By checking the façade parts that are the focus of the inspection periodically, it is possible to see which areas are warming up faster or slower during the day, and thus to make a distinction between problematic and non-problematic areas. Further critical success factors include the thermal sensitivity of the camera, the optimal spatial resolution of the best-suited lens, as well as the skills and expertise of the thermographic inspector.

Luca Del Nero is also an ITC and ISO9712 Level 3 thermographer and an international thermography instructor. He comments: “In our building applications, thermal imaging has always been the key to success. One of our specialties is the inspection of coatings, especially for diagnosis and appraisals in support of lawsuits, where destructive tests are usually not allowed. We have always used FLIR’s high resolution cameras and a complete set of lenses to always have the best spatial resolution and therefore have an excellent view of the condition of the facades.”

“We started with an amazing FLIR P640 camera, which is now obsolete, and then moved on to the FLIR T640. Now, we are looking forward to using the FLIR T1K with full HD resolution, so we can always offer the best service possible.”

Reliable results, high flexibility

“Ancillary tests that we routinely carry out during our thermal inspections have always confirmed the quality of our analyses,” says Luca Del Nero. “Today, at DarkWave Thermo, thermal imaging is our primary technique to assess the status of facades, the extent of the problems and to show us where to perform the detachment tests.”

Today, especially in urban areas that require flexibility and speed of execution and where setting up a platform or using other lifting techniques requires permits and sometimes involves prohibitive costs, thermal imaging is the most flexible and reliable option.

“Thermal imaging gives us reliable results, both for tile coatings and plaster buildings. For our inspections, we do not need to set up complicated and expensive lifting equipment or scaffolding, which is a big time and money saver. The FLIR cameras always give us a clear thermal picture of the problematic areas, from the ground and from a considerable distance.”